Separate Scrap PCB Board Process Plant Automatic Waste Lithium Battery Recycling Line

Introduction

Separate scrap PCB board into pure copper and resin powder. Before process PCB board need use the heating machine separate the electric parts away from the board because the boards including some valuable metals can be gain by some kind of chemical.

Equipment characteristics

The equipment can operate continuously, with high disassembly efficiency, and can automatically sort and recycle electronic components and solder from discarded circuit boards in one go; The electronic components are undamaged after disassembly and can continue to be used, extending their service life and increasing profit margins.

1. The disassembly process has a high degree of automation, reduces labor intensity, and saves manpower and time;

2. Adopting hot air circulation heating method, the furnace temperature uniformity is good;

3. Temperature controllable and fully functional;

4. The running speed of the conveyor system belt is continuously adjustable;

5. The equipment operates stably and reliably, and is easy to operate, use, and maintain;

6. Adopting an integrated structure of electrical control and furnace body, it effectively utilizes spatial location, occupies a small area, has a reasonable and compact equipment structure layout, and has a beautiful and elegant appearance design;

7. The discharged waste gas is centrally treated, and adsorbed and filtered to meet environmental standards.

Raw Material

Final Products

Process Analysis

The main board optical board of the circuit board is processed by a first level silent shredder to produce a 40 * 40MM block shape. After entering the second level ring hammer crusher, it is processed to 10 * 10MM particles. The PCB particles are then processed to 50 mesh fine powder by a third level grinder, and then enter the airflow gravity separator and electrostatic separator. The light resin powder flows to the high-voltage electrostatic separator at the tail outlet for secondary sorting, and the relatively heavy copper powder flows out at the front outlet, The entire process adopts automatic airflow transportation, and all dust is collected centrally by a pulse dust collector. The metal purity of copper powder can reach about 95%, and the metal recovery rate is 99.5%.

Equipment List

|

No.

|

Device Name

|

Power parameters

|

Quantity

|

Reference image

|

|

1

|

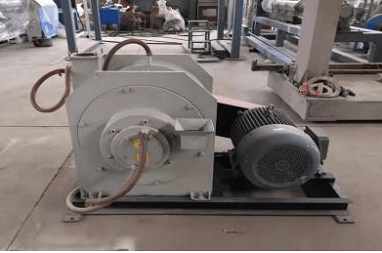

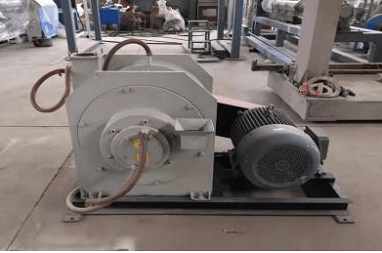

Shredder

|

1. Reducer ZQ gear structure

2. Motor 18.5KW * 2 sets

3. Tool material SKD11, diameter 320MM

4. National standard for pure copper motor

5. Speed 28r/min

6. Automatic overload device for electrical cabinet

7. Knife disc thickness 20mm, model 600

|

1set

|

|

|

2

|

Circuit board crusher

|

1: Heavy duty thickened casing thickness 16mm

2: Model 800 with a rotating diameter of 700mm

3: 45KW National Standard Pure Copper Wire Motor

4: 24 hammer heads and 24 blades

5: The rack is made of 140mm large channel steel

6: Upper box cover equipped with hydraulic booster structure

7: Screen aperture 14mm

|

1set

|

|

|

3

|

Circuit board grinding machine

|

1: Model 800 with a rotating diameter of 700mm

2: 45KW National Standard Pure Copper Wire Motor

3: The blade is made of wear-resistant white steel

4: Double layer circulating water cooling of the engine body

5: Quick and portable side cover opening method

6: Screen mesh with a diameter of 4mm

|

1set

|

|

|

4

|

Belt conveyor

|

1: Bandwidth of 600mm

2: Reducer chain transmission structure

3: PVC thickened canvas bag

4: Power 1.1KW

|

3set

|

|

|

5

|

Airflow conveyor grinding to gravity separation

|

1: Power 5.5KW

2: The cone is made of stainless steel

3: Installation of electric discharge valve at the discharge port

|

1set

|

|

|

6

|

Airflow conveyor reselection to static electricity

|

1: Power 5.5KW

2: The cone is made of stainless steel

3: Install anti blocking electric discharge valve at the discharge port

|

1set

|

|

|

7

|

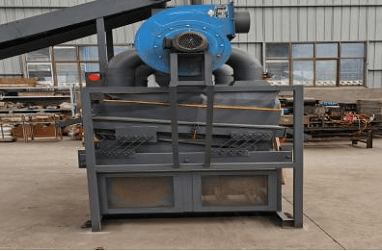

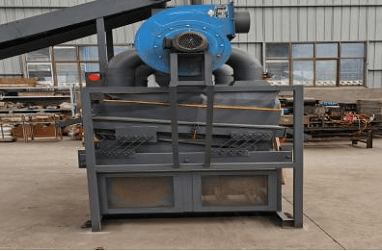

gravity separator

|

1: Power 6KW

2: Variable frequency adjustable vibration speed

3: Sorting net 800 X 1350mm

4: Variable frequency adjustment of blowing frequency

|

1set

|

|

|

8

|

High voltage electrostatic separator double roller type

|

1: Power 4KW

2: The electric roller adopts 304 high-precision round roller

3: Electric roller length 1800mm, diameter 330mm

4: The high-voltage generator adopts an imported motherboard

5: Double layer electric roller for upper and lower layers

|

1set

|

|

|

9

|

Pulse dust collector

|

1. Power 11kw

2.128 bags of needle felt filter bags

3. Bottom ash hopper and side quick inspection door

4. Install electric discharge valve at the outlet

|

1set

|

|

|

10

|

Dust collection pipeline

|

1: 400mm diameter

2: Galvanized spiral air duct

3: Flange connection method

|

1set

|

|

|

11

|

PLC

control cabinet

|

1: 1 crusher soft start cabinet

2: 1 soft start cabinet for the grinding machine

3: 1 shredder soft start cabinet

4: 1 set of other equipment combination electrical cabinet

|

|

|

|

12

|

fittings of a machine

|

1: 1 set of grinding machine blades and 1 set of lining plate

2: 1 set of crusher blades and 1 set of hammer head

3: 1 set of crusher screen

4: 1 set of grinding machine screen

5: 5 pieces of shrapnel from the sorting machine

6: 4 wear-resistant steel wire strips for the gravity separator

7: 3 electrostatic sorting machine sprockets

|

|

Extra calculate

|

en

en fr

fr de

de ru

ru es

es pt

pt ko

ko tr

tr pl

pl th

th

IPv6 network supported

IPv6 network supported