Oct 24 , 2023

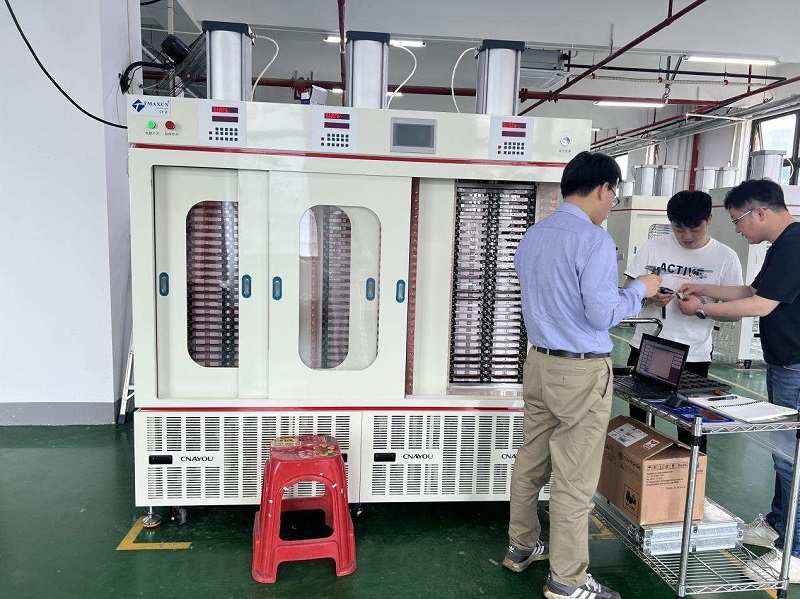

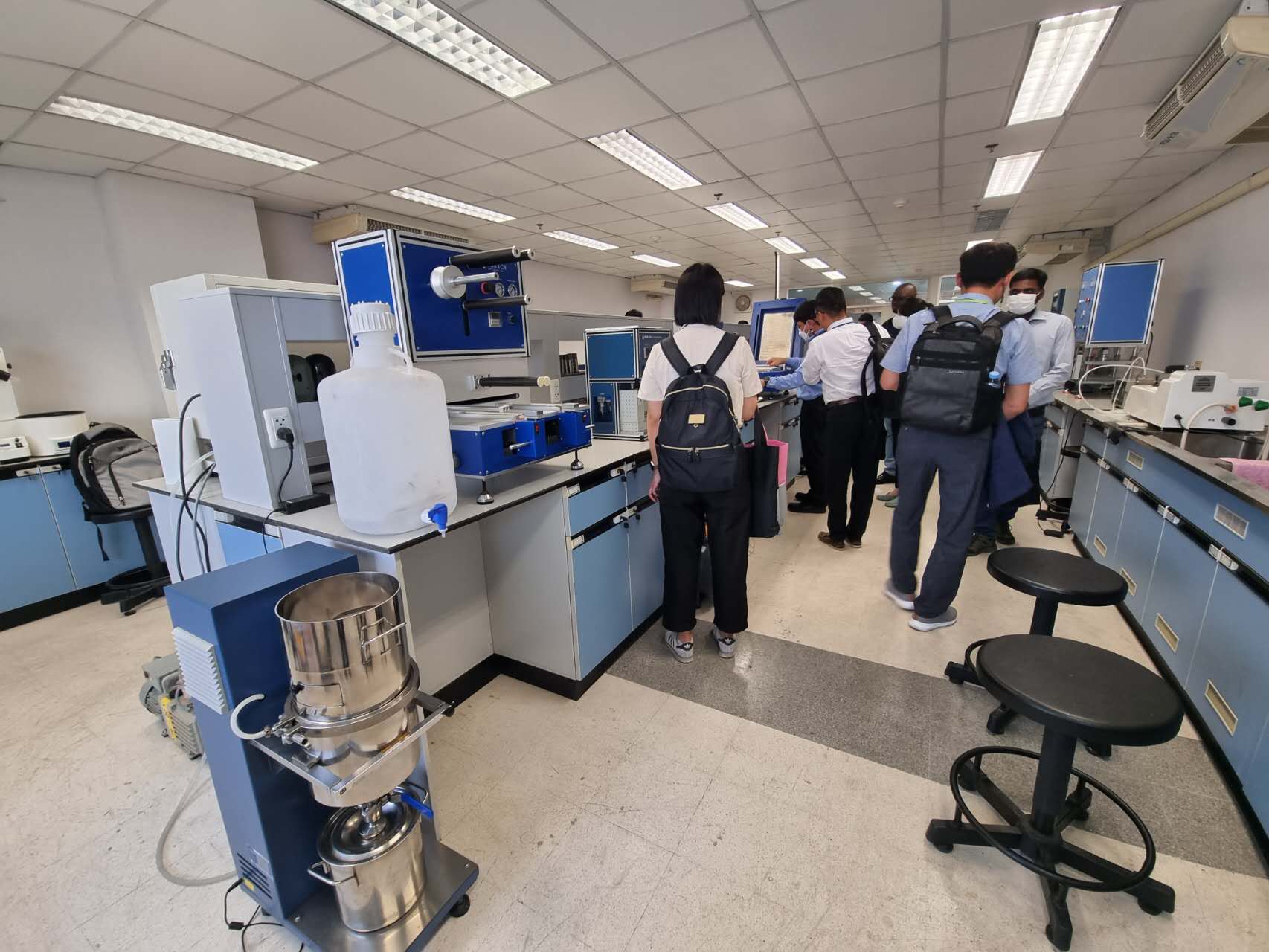

TMAX's Pouch Battery Production Line Successfully Passes Swedish Customer Acceptance We are pleased to announce that our latest pouch battery production line has received high praise from their Swedish customer after undergoing a rigorous acceptance process. This acceptance signifies TMAX's expertise in manufacturing production equipment and their unwavering commitment to quality. The acceptance work was conducted internally by a professional quality inspection team, who performed comprehensive tests and evaluations of the equipment's various functions. The results demonstrated that all the equipment met the company's stringent quality standards, showcasing their outstanding performance and high quality. This pouch cell production line includes: Electrode Manufacturing -->Cell Assembly -->Cell Finishing. This includes equipment such as 650L double planetary mixer, single layer slot die coating machines, D600*650mm rolling press calender, 1200W high speed electrode slitting machine, electrode laser die-cutting machine, pouch cell stacking machines, pouch cell forming machines, pouch cell top and side sealing machine, and 5V 100A pouch cell formation testing equipment etc. The required equipment includes mixers, coating machines, calenders, slitting machines, die-cutting machines, stacking machines, forming machines, sealing machines, and formation testing equipment. This successful acceptance reaffirms TMAX's technical competence and their dedication to ensuring top-notch quality in production equipment. The company will continue to strive for improved product quality and enhanced production efficiency to provide customers with superior products and services.

en

en fr

fr de

de ru

ru es

es pt

pt ko

ko tr

tr pl

pl th

th

IPv6 network supported

IPv6 network supported