Wechat:17720812054 Whatsapp:+86 13174506016 Email:David@batterymaking.com

- Home

- Company

- Products

- Lithium Battery Production Machine Line

- Lithium Battery Lab Pilot Machine Line

- Lithium Battery Pack Assembly Machine Line

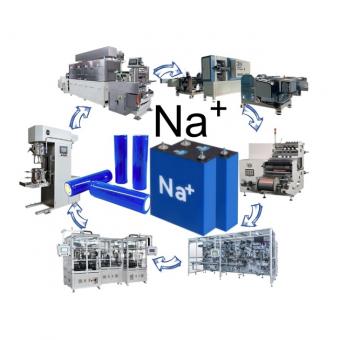

- Sodium Ion Battery Manufacturing Line

- Supercapacitor Assembly Machine Line

- Lithium Battery Assembly Plant

- Solid-state Battery Assembly Line

- Lithium Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Customized Battery Electrode

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Lithium Chip

- Lithium Ion Battery Recycling Production Line

- Lithium Battery Assembly Machine

- Battery Tester

- Battery Safety Analyser

- Battery Material Analyser

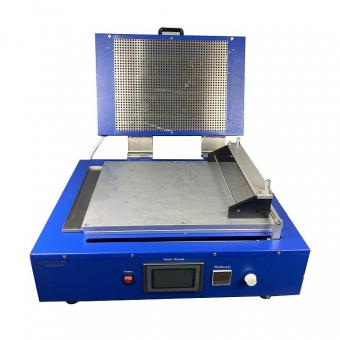

- Electrode Coating Machine

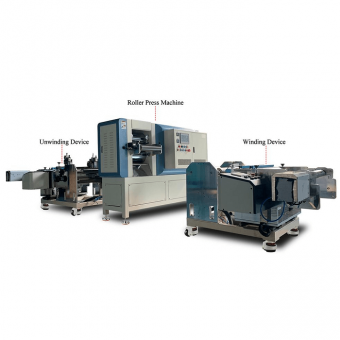

- Electrode Roll Press Machine

- Vacuum Mixer

- Coin Cell Crimper

- Coin Cell Disc Punching Machine

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welding Machine

- Pouch Cell Electrode Die Cutter

- Cylindrical Cell Sealing and Disassembling

- Cylindrical Cell Grooving Machine

- Cylindrical Cell Electrode Slitting

- Cylindrical Cell Electrode Winding

- Cylindrical Cell Spot Welding

- Electrolyte Injector

- NMP Waste Recovery System

- Lithium Battery Pack Machine

- Dry Electrode Preparation Solution

- Laboratory Machine

- Metal Foam

- Video

- Projects

- Certificates

- Contact

- COOPERATIVE CLIENTS

en

en fr

fr de

de ru

ru es

es pt

pt ko

ko tr

tr pl

pl th

th

IPv6 network supported

IPv6 network supported