Intelligent panel

Controller foolproof operation, more convenient, simple, with glass touch panel more upscale.

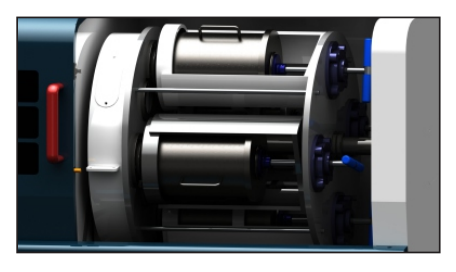

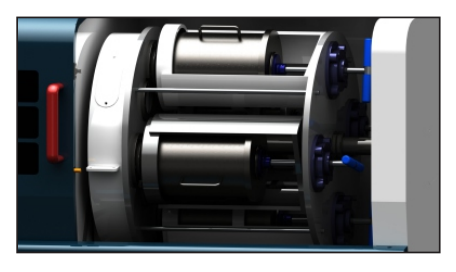

Horizontal planetary drive structure

Adopting double planetary disk supporting bracket structure at both ends to ensure stable operation of the equipment.

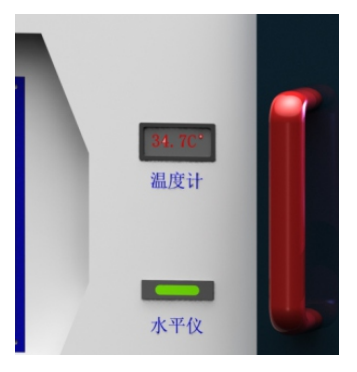

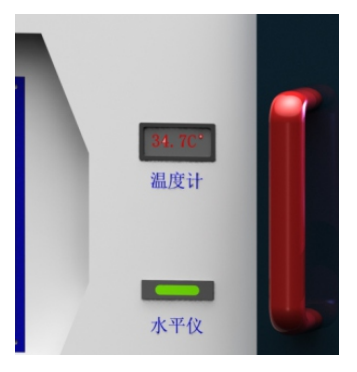

Temperature monitoring and leveling ball

Thermometer is installed in the ball mill cavity to monitor the approximate temperature of the ball milled material in real time, which is convenient to maintain the stability of the material characteristics. The equipment is installed with a level meter, which is convenient for debugging the level of the equipment and keeping the equipment stable.

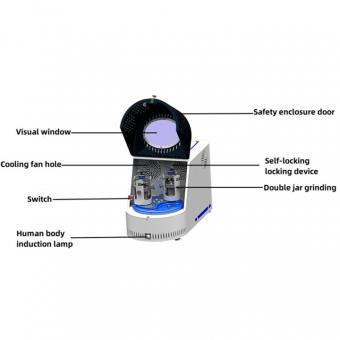

Sensor light device

The working light is controlled by infrared human body sensor, the light is on when people come and off when people leave, which is convenient and energy-saving.

Omni-directional planetary ball mill is on the basis of vertical planetary ball mill, increased planetary drive mechanism flip function, planetary disc and ball mill jar materials, grinding balls in the planetary movement at the same time, but also in a fixed space within the scope of a 360 ° flip to realize the ball mill jar grinding balls and materials multi-dimensional multi-directional movement, to enhance the degree of grinding balls and materials in disordered movement, the entire material in the mill jar grinding dead angle, so that the material is more uniform, and to solve the problem of some of the material sinking and sticking to the jar. The whole material is ground in the grinding jar without dead angle, so that the material is more uniform, and can solve the problem of part of the material sinking to the bottom and sticking to the jar.

Product performance

|

Transmission mode

|

Gear drive

|

|

Working method

|

Simultaneous operation of two or four ball milling jars

|

|

Maximum loading capacity

|

Two thirds of the volume of the ball milling jars

|

|

Volume of ball milling jar

|

Each jar 1.5L-25L, total volume 0.2L-100L

|

|

Feeding granularity

|

Soil material≤10mm, other materials≤3mm

|

|

Discharge size

|

Minimum 0.1um

|

|

Rotation speed ratio (RPM:SR)

|

See the main parameters of planetary ball mill

|

|

Speed (Rotation)

|

See the main parameters of planetary ball mill

|

|

Speed control mode

|

Brand inverter stepless speed regulation

|

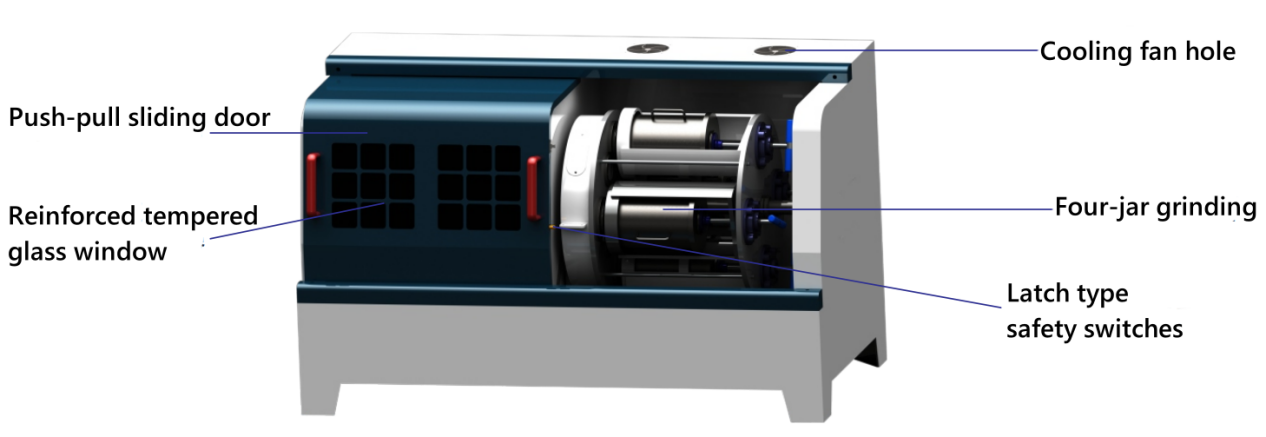

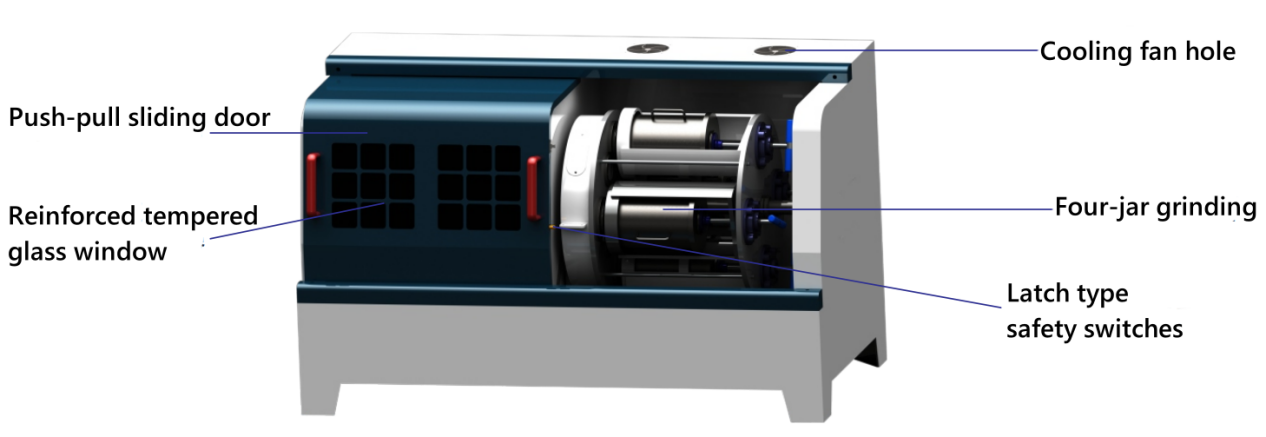

1. Appearance modeling design

Adopting thickened steel plate profile welding molding processing technology, high strength, impact resistance, atmosphere and stability, in line with international and domestic aesthetic needs.

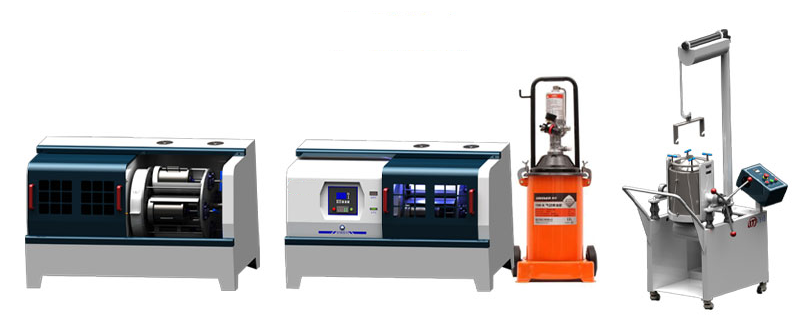

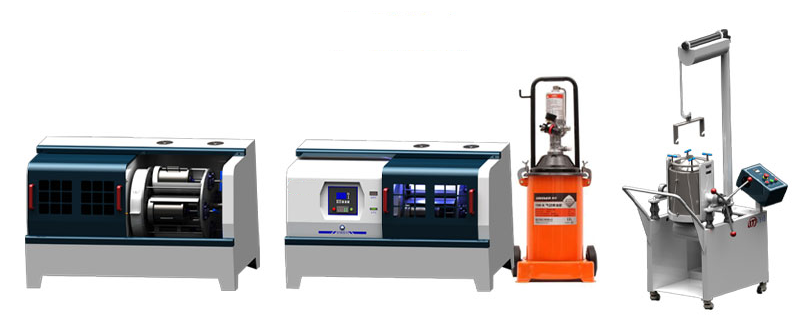

2. Automatic grease adding device

Through the grease host electronic control, flexible design time cycle automatic quantitative lubricating grease, solve the wear and tear due to untimely lubrication of transmission components, shorten the service life of the equipment.

3. Matching lifting and dumping device

Pouring device is integrated with vibrating screen discharging technology, which is simple and easy to operate, realizing fast can picking, unloading and loading, and improving production efficiency.

|

Model

|

Volume

(L)

|

Jar volume

|

Qty

|

Matching ball

milling jars

|

Ball mill jar locking and anti-loosening

device as standard.

|

Standard manual positioning (optional automatic positioning device)

|

|

HPBM-6

|

6

|

1-1.5L

|

4

|

50-1000ml vacuum ball milling jars available

|

Manual

|

Manual

|

|

HPBM-8

|

8

|

1-2L

|

4

|

50-1500ml vacuum ball milling jars available

|

Manual

|

Manual

|

|

HPBM-10

|

10

|

1-2.5L

|

4

|

1-2L vacuum ball milling jars available

|

Manual

|

Manual

|

|

HPBM-12

|

12

|

1-3L

|

4

|

1-2L vacuum ball milling jars available

|

Manual

|

Manual

|

|

HPBM-16

|

16

|

2-4L

|

4

|

1-3L vacuum ball milling jars available

|

Manual

|

Manual

|

|

HPBM-20

|

20

|

2-5L

|

4

|

2-4L vacuum ball milling jars available

|

Manual

|

Manual

|

|

HPBM-40

|

40

|

5-10L

|

4

|

5-10L vacuum ball milling jars available

|

Manual

|

Manual

|

|

HPBM-60

|

60

|

10-15L

|

4

|

10-15L vacuum ball milling jars available

|

Manual

|

Manual

|

|

HPBM-80

|

80

|

15-20L

|

4

|

15-20L vacuum ball milling jars available

|

Manual

|

Manual

|

|

HPBM-100

|

100

|

20-25L

|

4

|

15-20L vacuum ball milling jars are available.

|

Manual

|

Manual

|

|

Model

|

Equipment power supply

|

Motor power(KW)

|

Total running setup time(min)

|

Forward and reverse run time (min)

|

Adjustable speed(rpm) Rotation(rpm)

|

|

HPBM-6

|

Single-phase 220V-50HZ

|

1.1

|

1-9999

|

1-999

|

35-370

|

70-740

|

|

HPBM-8

|

Three-phase 380V-50HZ

|

1.5

|

1-9999

|

1-999

|

35-320

|

70-640

|

|

HPBM-10

|

Three-phase 380V-50HZ

|

1.5

|

1-9999

|

1-999

|

35-320

|

70-640

|

|

HPBM-12

|

Three-phase 380V-50HZ

|

1.5

|

1-9999

|

1-999

|

35-320

|

70-640

|

|

HPBM-16

|

Three-phase 380V-50HZ

|

3

|

1-9999

|

1-999

|

30-240

|

60-480

|

|

HPBM-20

|

Three-phase 380V-50HZ

|

4

|

1-9999

|

1-999

|

25-215

|

50-430

|

|

HPBM-40

|

Three-phase 380V-50HZ

|

5.5

|

1-9999

|

1-999

|

25-215

|

50-430

|

|

HPBM-60

|

Three-phase 380V-50HZ

|

7.5

|

1-9999

|

1-999

|

25-170

|

50-340

|

|

HPBM-80

|

Three-phase 380V-50HZ

|

11

|

1-9999

|

1-999

|

25-155

|

50-310

|

|

HPBM-100

|

Three-phase 380V-50HZ

|

11

|

1-9999

|

1-999

|

25-155

|

50-310

|

|

Model

|

Standard panel (optional touch screen)

|

Lubrication method (optional automatic grease filling device)

|

Speed control mode

|

Equipment reference weight (Kg)

|

Equipment Reference Dimensions

Length x Width x Height (mm)

|

Noises ≤db

|

|

HPBM-6

|

Intelligent

|

Grease

|

Frequency conversion

|

90

|

1120x600x710

|

60±5

|

|

HPBM-8

|

Intelligent

|

Grease

|

Frequency conversion

|

375

|

1300x620x870

|

60±5

|

|

HPBM-10

|

Intelligent

|

Grease

|

Frequency conversion

|

375

|

1300x620x870

|

60±5

|

|

HPBM-12

|

Intelligent

|

Grease

|

Frequency conversion

|

375

|

1300x620x870

|

60±5

|

|

HPBM-16

|

Intelligent

|

Grease

|

Frequency conversion

|

450

|

1480x700x900

|

60±5

|

|

HPBM-20

|

Intelligent

|

Grease

|

Frequency conversion

|

710

|

1600x820x1000

|

65±5

|

|

HPBM-40

|

Intelligent

|

Grease

|

Frequency conversion

|

770

|

1700x810x1000

|

65±5

|

|

HPBM-60

|

Intelligent

|

Grease

|

Frequency conversion

|

1040

|

1800x1050x1180

|

65±5

|

|

HPBM-80

|

Intelligent

|

Grease

|

Frequency conversion

|

1180

|

1995x1110x1260

|

68±5

|

|

HPBM-100

|

Intelligent

|

Grease

|

Frequency conversion

|

1180

|

1995x1110x1260

|

68±5

|

Equipment lightweight push-pull door easy to operate, the shell using high-precision laser cutting, CNC bending molding, generous and exquisite, high-end and stable, planetary disk, structural components using CNC machining process, nitriding metal heat treatment process to ensure that the rotating shaft parts wear-resistant to prevent shaft breakage, the transmission gear selection of high-temperature wear-resistant non-metallic and metal combinations of precision gears, lubrication with grease lubrication, can be equipped with our automatic grease lubrication device, flexible settings for how long automatic quantitative refueling, to solve the problem of wear due to untimely lubrication of transmission components, shortening the service life of the equipment, to ensure that equipment running at high speeds, smooth and quiet. The device can be equipped with our automatic grease lubrication device, which can be set flexibly to automatically quantitatively refuel for a long time, solving the problem of wear and tear due to untimely lubrication of the transmission components, shortening the service life of the equipment, and ensuring the equipment to run smoothly and quietly at high speeds.

Planetary mill is an indispensable equipment for high-tech material mixing, fine grinding, sample making, nanometer material dispersion, new product development and small batch production. The product is small in size, full-featured and high in efficiency. It is the ideal equipment for scientific research institutions, universities and enterprise laboratories to obtain particulate research samples (each experiment can obtain four samples at the same time). Grinding samples under vacuum.

Widely used in geology, minerals, metallurgy, electronics, building materials, ceramics, chemical industry, light industry, cosmetology, environmental protection and other sectors, such as: electronic ceramics, structural ceramics, magnetic materials, lithium cobaltate, lithium manganese oxide, catalysts, phosphor, long afterglow luminescent powders, rare-earth polishing powders, electronic glass powders, fuel cells, ceramic capacitors, zinc oxide piezoresistors, piezoceramics, nano-materials, wafer ceramic capacitors, MLCC, thermistor (PTC, NTC), ZnO varistor, arrester valve, strontium titanate ring varistor, ceramic filter, dielectric ceramics, piezoelectric transducer, piezoelectric transformer, chip resistor, thick film circuit, pyroelectric potentiometers, alumina ceramics, zirconium oxide ceramics, fluorescent powders, zinc oxide powders, cobalt oxide powders, nickel-zinc ferrite, manganese-zinc ferrite and other industry products.

Planetary Pulverizer is designed for pulverizing, grinding and dispersing metallic, non-metallic, organic and other powders. Especially suitable for laboratory research use. Strong shearing, impact and crushing can achieve the purpose of crushing, grinding, dispersing and emulsifying materials. The planetary ball mill is equipped with four ball milling pots on the same turntable. When the turntable rotates, the ball milling pots rotate around the turntable axis, and at the same time rotate around their own axis, making planetary motion. The grinding balls in the pots collide with each other in high-speed motion to grind and mix the sample. The product can be used for dry and wet grinding and mixing products of different particle sizes and materials. The Z-small particle size of the ground product can be as small as 0.1 micron. It meets the requirements of various process parameters very well. At the same time, due to the advantages of small batch, low power consumption and low price, it is the first choice for schools, scientific research units and enterprises to carry out research on crushing technology, new materials and coatings.

en

en fr

fr de

de ru

ru es

es pt

pt ko

ko tr

tr pl

pl th

th

IPv6 network supported

IPv6 network supported