Battery Production Line: Equipment, Advantages, and Production Considerations

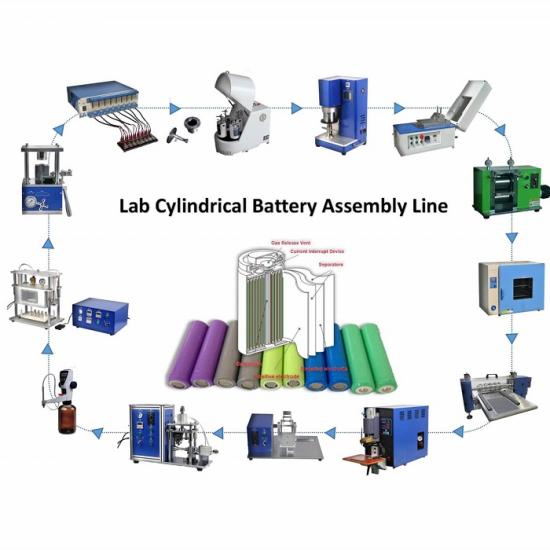

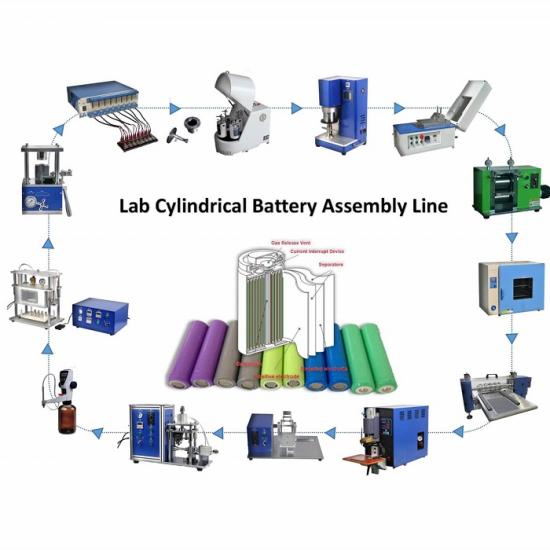

The production of batteries is a complex process that requires a variety of equipment and careful attention to detail. A battery production line typically consists of several stages, including electrode preparation, cell assembly, testing, and packaging. In this article, we will discuss the equipment used in each stage, the advantages of a battery production line, and some important considerations for ensuring successful production.

Equipment Used in Battery Production Line

Electrode Preparation Stage

The electrode preparation stage involves the preparation of positive and negative electrodes. The equipment used in this stage typically includes

Roll To Roll Electrode Coater Coating Machine, drying ovens, and slitting machines.

Cell Assembly Stage

The cell assembly stage involves the assembly of positive and negative electrodes, separator, electrolyte, and other materials to create a battery cell. The equipment used in this stage includes winding machines,

spot welding machines,

electrolyte filling machines, and cell sealing machines.

Testing Stage

The testing stage involves the testing of the completed battery cells to ensure they meet the required specifications. The equipment used in this stage includes battery testers and sorting machines.

Packaging Stage

The packaging stage involves the packaging of the completed battery cells into final products such as battery packs or individual batteries. The equipment used in this stage includes packaging machines and labeling machines.

Advantages of a Battery Production Line

High Efficiency

A battery production line enables the automation of many steps in the production process, resulting in increased efficiency and reduced labor costs.

Consistent Quality

The use of automated equipment in a battery production line results in consistent quality and reduces the likelihood of errors or defects in the final product.

Customization

Battery production lines can be designed to accommodate various types and sizes of batteries, enabling the production of customized products to meet specific customer needs.

Considerations for Successful Production

Safety

Battery production involves the use of hazardous materials and equipment. Therefore, it is crucial to follow strict safety procedures and provide appropriate training to ensure the safety of workers and the production facility.

Quality Control

Quality control measures must be implemented at every stage of the production process to ensure that the final product meets the required specifications.

Maintenance

Regular maintenance of equipment is necessary to ensure optimal performance and prevent downtime that can impact production efficiency.

In conclusion, a battery production line involves a range of equipment and stages, from electrode preparation to final packaging. The use of automated equipment in a battery production line offers several advantages, including high efficiency, consistent quality, and customization. However, careful attention must be paid to safety, quality control, and equipment maintenance to ensure successful production.

en

en fr

fr de

de ru

ru es

es pt

pt ko

ko tr

tr pl

pl th

th

IPv6 network supported

IPv6 network supported