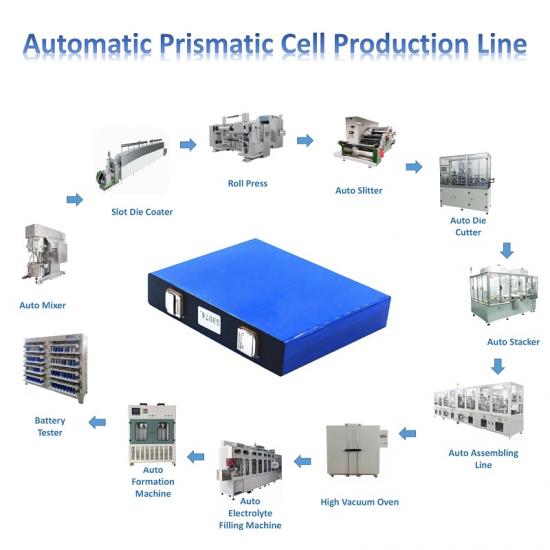

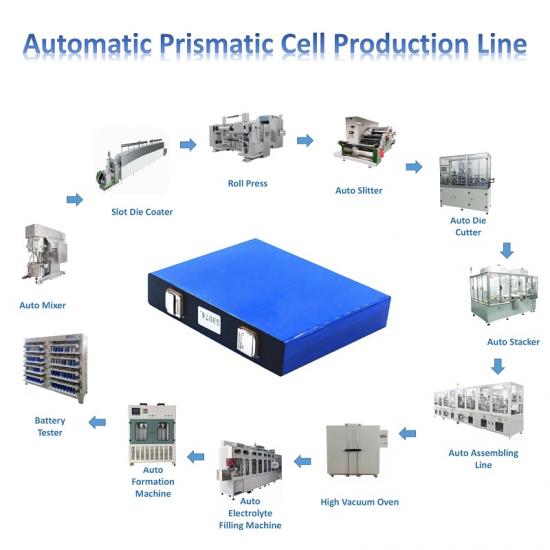

Prismatic cell manufacturing line are specialized equipment designed for the production of prismatic lithium-ion cells. These machines are used in battery manufacturing facilities to automate and streamline the various processes involved in producing prismatic cells. Here is an introduction to prismatic cell manufacturing machines and their practical applications:

Electrode Coating Machine:

Application: The electrode coating machine is used to apply the active materials (cathode and anode) onto metal foil substrates. It ensures precise coating thickness and uniform distribution of the active materials. This machine is essential for achieving optimal electrode performance, enhancing battery capacity, and maintaining consistent cell performance.

Electrode Cutting and Stacking Machine:

Application: The electrode cutting and stacking machine is responsible for cutting the coated electrode sheets into specific dimensions and stacking them with separator layers. It enables the precise alignment and stacking of electrodes, ensuring uniform electrode distribution and minimizing the risk of short circuits. This machine plays a crucial role in achieving the desired electrode geometry and structural integrity.

Cell Assembly Machine:

Application: The Prismatic cell assembly line automates the process of assembling the electrode assemblies, separator layers, and current collectors into prismatic cell configurations. It ensures accurate alignment, positioning, and connection of the components, resulting in reliable and consistent cell assembly. This machine enables high-volume production and improves the efficiency and repeatability of the cell assembly process.

Electrolyte Filling and Cell Sealing Machine:

Application: The electrolyte filling and cell sealing machine is used to fill the assembled prismatic cells with electrolyte and hermetically seal them. It ensures precise and controlled electrolyte filling, preventing overfilling or underfilling that could affect cell performance and safety. The sealing process ensures the integrity of the cells, preventing electrolyte leakage and protecting against external contaminants.

Cell Formation and Testing Equipment:

Application: Cell formation equipment is used to subject the sealed prismatic cells to specific temperature, voltage, and current profiles. This process activates the cell chemistry and stabilizes its performance characteristics. Testing equipment is used to evaluate the electrical properties of the cells, including capacity, voltage, internal resistance, and cycle life. These machines ensure that the prismatic cells meet quality standards and performance specifications before they are used in battery packs or other applications.

By employing prismatic cell production plant battery manufacturers can achieve precise control over the fabrication processes, improve production efficiency, and ensure consistent cell quality. These machines enable the mass production of prismatic cells with high accuracy, reliability, and performance, meeting the growing demand for advanced lithium-ion batteries in various industries.

en

en fr

fr de

de ru

ru es

es pt

pt ko

ko tr

tr pl

pl th

th

IPv6 network supported

IPv6 network supported