Prismatic Cell: Unlike cylindrical cells like the 18650, prismatic cells have a rectangular or square shape. They are commonly used in applications where space efficiency is crucial, such as electric vehicles.

Laboratory Machine: This could encompass a variety of equipment designed for different stages of the battery development and testing process. Here are some possible components:

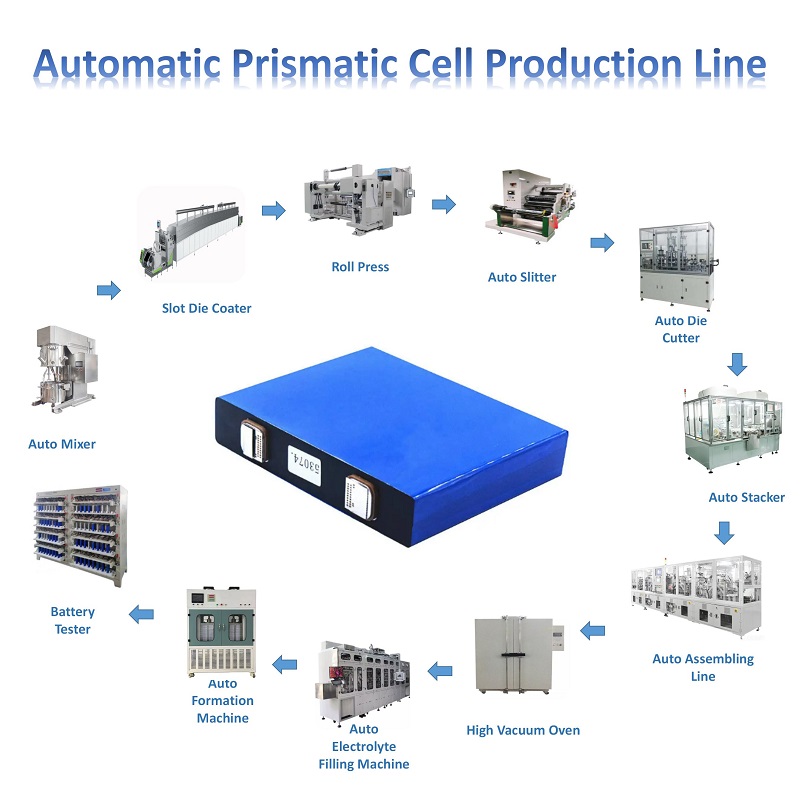

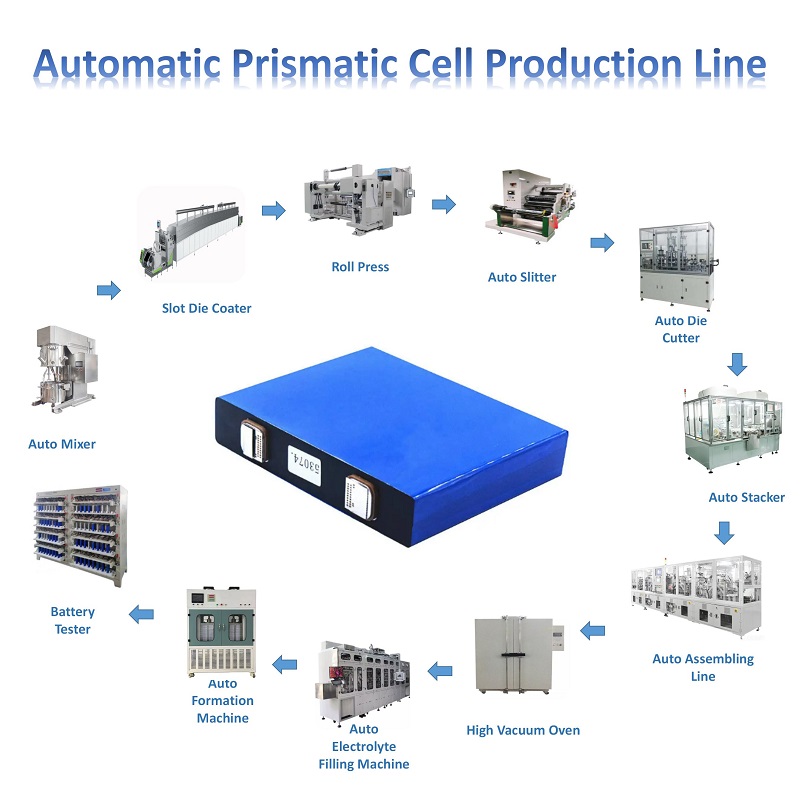

Prismatic cell production line:

Materials Preparation: These machines handle the mixing of electrode materials, such as cathode and anode materials, binders, and conductive additives.

Coating Process: Equipment for applying a uniform coating of electrode materials onto current collectors, ensuring proper adhesion and conductivity.

Calendaring Equipment:

Electrode Calendaring machine compress and shape the coated electrode materials to the desired thickness, ensuring uniformity and density.

Assembly Machines:

Stacking and Alignment: Automated systems for precisely stacking and aligning the electrodes to form the prismatic cell structure.

Sealing: Equipment for sealing the prismatic cell to prevent leakage and ensure airtightness.

Testing Equipment:

Capacity Testing: Machines to assess the capacity of the prismatic cells, measuring their ability to store and deliver electrical energy.

Voltage Testing: Instruments for evaluating the voltage characteristics of the cells during charge and discharge cycles.

Cycle Life Testing: Systems to simulate and evaluate the number of charge-discharge cycles a prismatic cell can undergo while maintaining performance.

Thermal Testing: Equipment to assess the thermal behavior of prismatic cells, including heat generation and dissipation characteristics.

Safety Testing: Machines to evaluate safety features, such as response to overcharging, short circuits, and temperature extremes.

Formation Equipment:

Cycle Conditioning: Machines for subjecting prismatic cells to repeated charge and discharge cycles to stabilize and activate them.

Capacity Matching: Equipment to ensure consistent performance and capacity across a batch of prismatic cells.

Quality Control and Characterization Tools:

Analytical Instruments: Tools like scanning electron microscopes (SEM) and X-ray diffraction (XRD) for detailed analysis of the microstructure and composition of electrode materials.

Impedance Spectroscopy: Used for analyzing the electrical properties of prismatic cells and identifying factors influencing performance.

Research and Development Facilities:

Prismatic cell manufacturing line: Facilities for developing and testing prototype prismatic cells with innovative designs and materials.

Material Research: Laboratories equipped for studying and experimenting with new electrode materials, electrolytes, and separators.

Data Collection and Analysis Tools:

Data Logging Systems: Software and tools for collecting and analyzing data from various tests, providing insights into the performance and behavior of prismatic cells.

By combining these elements, a prismatic cell laboratory machine setup provides a comprehensive environment for developing, testing, and refining prismatic lithium-ion battery cells. Each stage of the process is carefully controlled and monitored to ensure the production of high-quality and reliable prismatic cells.

en

en fr

fr de

de ru

ru es

es pt

pt ko

ko tr

tr pl

pl th

th

IPv6 network supported

IPv6 network supported