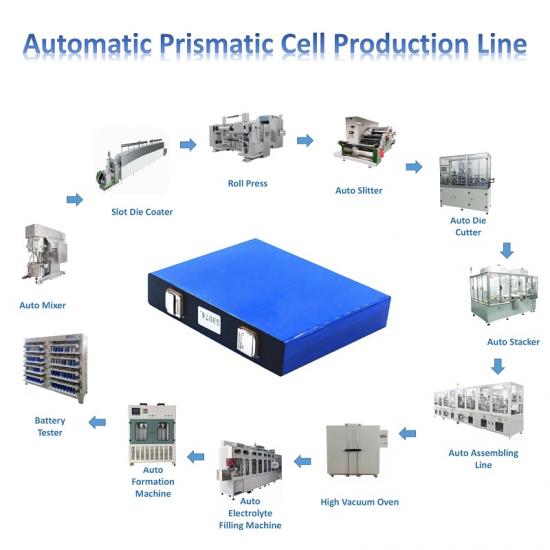

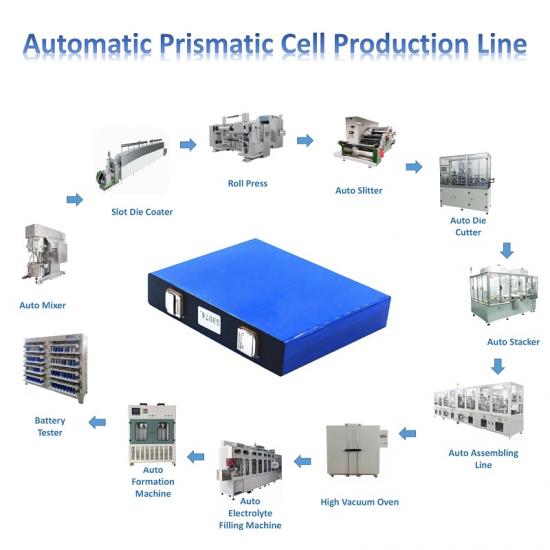

Lithium Battery manufacturing line are used for the mass production of batteries, including lithium-ion batteries, nickel-metal hydride batteries, and other types of rechargeable batteries. These lines involve several key processes, each requiring specific equipment. Here are the common applications and equipment involved in different stages of a battery manufacturing line:

Electrode Preparation:

Coating: Electrode Coating machine are used to apply electrode materials onto current collector foils, typically using a slurry-based coating process.

Drying: Drying ovens or drying chambers are employed to remove solvents and moisture from the coated electrodes.

Calendaring: Calendaring machines compress and smooth the coated electrodes to achieve uniform thickness and density.

Electrode Assembly:

Slitting: Electrode Slitting machine are used to cut the coated electrode sheets into narrower strips for further processing.

Stacking: Stacking machines arrange the electrode strips, separator layers, and current collectors into electrode assemblies, also known as jelly rolls.

Tab Welding: Tab welding equipment joins the electrode tabs to the current collectors to establish electrical connections.

Cell Assembly:

Cell Formation: battery formation equipment fills the electrode assemblies with electrolyte and assembles them with cell housing, creating individual battery cells.

Cell Sealing: Sealing machines hermetically seal the assembled battery cells to prevent leakage and ensure safety.

Aging: Aging chambers subject the sealed cells to specific temperature and voltage conditions for a predetermined period to stabilize their performance.

Battery Testing:

Performance Testing: Battery testing systems measure the electrical performance characteristics of the manufactured batteries, including capacity, voltage, internal resistance, and cycle life.

Safety Testing: Safety testing equipment verifies the compliance of batteries with safety standards by subjecting them to various tests, such as short circuit, overcharge, and thermal abuse tests.

Battery Pack Assembly:

Pack Integration: Pack integration machines assemble multiple battery cells into a complete battery pack, along with the necessary electronics, connectors, and thermal management components.

Enclosure Assembly: Enclosure assembly equipment combines the battery pack with the required housing, wiring, and protective features to create a finished battery pack.

Quality Control and Inspection:

Vision Systems: Vision inspection systems use cameras and image processing algorithms to detect defects, such as electrode misalignment, coating irregularities, or cell swelling.

Quality Control Stations: These stations perform thorough quality checks, including visual inspections, electrical testing, and functional testing, to ensure the overall quality and performance of the batteries.

It's important to note that the specific equipment used in battery manufacturing lines can vary depending on the battery chemistry, size, and production scale. Manufacturers may employ customized or specialized machinery tailored to their specific production needs. Additionally, automation and robotics play a significant role in modern battery manufacturing lines to improve efficiency, accuracy, and productivity.

en

en fr

fr de

de ru

ru es

es pt

pt ko

ko tr

tr pl

pl th

th

IPv6 network supported

IPv6 network supported